PTFE INSULATED RTD CABLE

PTFE Insulated RTD Cables serve critical roles in various applications where precision and reliability are paramount.

Construction of PTFE Insulated RTD Cables

Conductors : These cables typically consist of multiple conductors.

Core Insulation : The conductors are insulated with PTFE (Polytetrafluoroethylene), a synthetic fluoropolymer known for its exceptional thermal and electrical properties.

Shielding : PTFE RTD cables may have shielding to protect against electromagnetic interference (EMI).

Jacket : The outer jacket is also made of PTFE, providing additional insulation and protection.

Applications of PTFE Insulated RTD Cables::

RTD Sensors : PTFE-insulated RTD cables transmit signals from Resistance Temperature Detectors (RTDs) to control units. These cables ensure accurate temperature measurement and stability.

Core Insulation : The conductors are insulated with PTFE (Polytetrafluoroethylene), a synthetic fluoropolymer known for its exceptional thermal and electrical properties.

Industrial Processes : RTD cables are used in industries such as steel, cement, and chemical plants. They withstand high environmental temperatures near rotary kilns and furnaces.

Temperature Range : PTFE RTD cables can handle temperatures ranging from -65°C to +250°C.

Chemical and Moisture Resistance : PTFE insulation protects against chemical exposure and moisture.

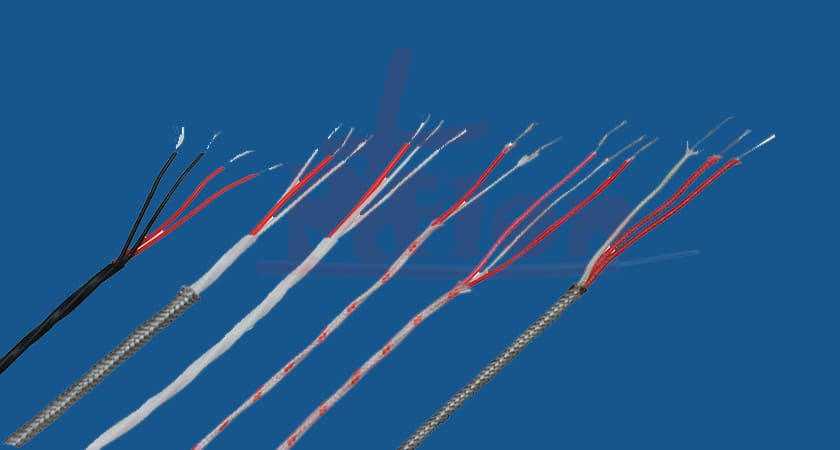

Customization : Available in various core configurations (2-core, 3-core, 4-core, etc.) based on specific requirements.

Shielding Options : Depending on the application, they can be SPC shielded or have an outside SS metal braid.

High Reliability : Ideal for critical installations where accuracy and durability are essential.

Advantages of PTFE Insulated RTD Cables :

Heat Resistance : PTFE sleeves safeguard against extreme heat and flames.

Mechanical Strength : Certified PTFE wire jackets provide mechanical robustness.

Anti-Stick Properties : PTFE prevents sediment buildup and fungal growth.

Preventing Equipment Damage : Insulated sleeves prevent equipment damage and electrical leakage.

High-Quality Manufacturing : Skilled professionals create these cables using top-quality raw materials and advanced technology.

Leave a Comment